Karakuri Kaizen and Dynamic Shelving Systems: A Path to Lean and Efficient Production

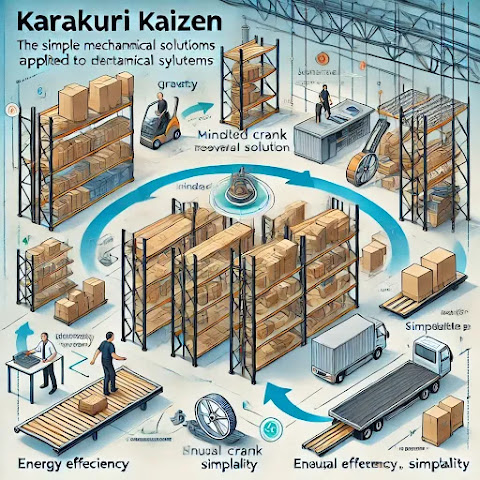

In today’s competitive manufacturing environment, energy efficiency and operational productivity not only reduce costs but also support environmental sustainability. Originating from Japan, the Karakuri Kaizen system represents an innovative extension of lean production philosophy. This mechanical solution minimizes the need for electricity or complex automation systems, enabling businesses to reduce costs while embracing eco-friendly production practices.

In this article, we delve into the principles of Karakuri Kaizen, its application in dynamic shelving systems, the benefits it offers, and steps for adaptation.

What is Karakuri Kaizen?

Karakuri Kaizen is a mechanical system that optimizes workflows using minimal energy resources, developed within the framework of lean production principles. In Japanese, “Karakuri” refers to simple machines or mechanical devices, while “Kaizen” means continuous improvement. Together, these concepts empower businesses to streamline processes with straightforward yet effective mechanical tools.

One of Karakuri Kaizen’s standout features is its reliance on natural energy sources such as gravity, spring mechanisms, and human power, eliminating the need for electricity or software. It is widely used in production and warehouse management processes.

How Do Karakuri Kaizen Dynamic Shelving Systems Work?

Dynamic shelving systems involve mechanisms that move, rotate, or transport materials across different locations or levels. Karakuri Kaizen optimizes this process using the following approaches:

Gravity-Powered Shelving: Inclined racks enable items to naturally move from one end to the other, accelerating workflows without requiring energy input.

Manual Mechanical Systems: Racks equipped with rollers, springs, or levers facilitate material movement between levels. Employees can activate the system with minimal effort.

Rotating Shelf Systems: Horizontal or vertical rotation allows easy access to stored items, especially in storage management scenarios.

Each solution relies on simple mechanical designs that are user-friendly in terms of assembly and maintenance.

Benefits of Karakuri Kaizen in Production

Karakuri Kaizen offers the following advantages:

Energy Savings: The system operates independently of electric power, reducing energy consumption and carbon footprints.

Cost Efficiency: Mechanical designs are more affordable than complex automation systems and easier to implement.

Ease of Maintenance: The system's standard mechanical components are robust and require minimal upkeep.

Environmental Sustainability: Leveraging natural energy reduces environmental impact, aligning with green production goals.

Flexibility and Adaptability: Karakuri Kaizen systems can be customized to meet the needs of various industries.

Adapting Karakuri Kaizen to Your Business

To implement Karakuri Kaizen in your operations, follow these steps:

Needs Analysis: Evaluate energy consumption, costs, and workflow efficiency to identify areas for improvement.

Design Simple Solutions: Explore the potential use of gravity, rollers, springs, and other mechanical elements.

Develop Prototypes: Test a basic Karakuri solution in a controlled environment.

Employee Training: Train staff on the proper usage and maintenance of the system.

Continuous Improvement: Regularly assess the system’s performance and make enhancements following Kaizen principles.

Conclusion

Karakuri Kaizen is a cornerstone of lean production, offering benefits such as energy savings, cost reduction, and environmental sustainability. In applications like dynamic shelving systems, it simplifies workflows, lowers costs, and enhances productivity. By adopting Karakuri Kaizen, businesses can achieve a sustainable and cost-effective approach to production.

Start your lean production journey today by exploring the benefits of Karakuri Kaizen for your processes. Remember, every significant transformation begins with a small yet impactful step.

Comments