Electrical Components in Circuits: Functions, Differences, and Occupational Safety and Health Importance

Electrical Components in Circuits: Functions, Differences, and Occupational Safety and Health Importance

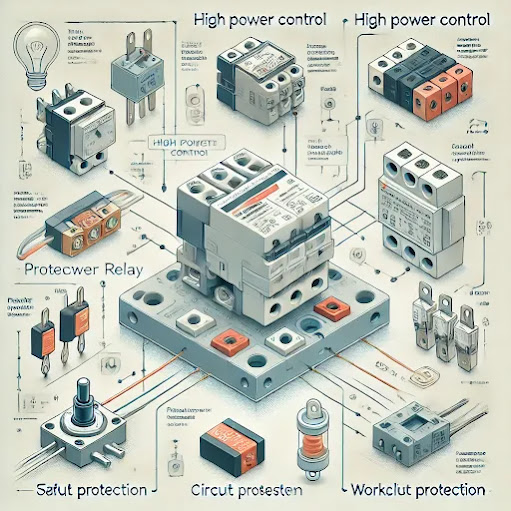

Electrical circuits utilize various components like contactors, protection relays, fuses, switches, and sensors to ensure operational safety, prevent electrical hazards, and comply with occupational health and safety standards. Each of these components plays a unique role in maintaining the integrity and functionality of electrical systems.

1. What is a Contactor?

A contactor is an electrical switching device designed to control high electrical currents. It primarily operates based on an electromagnet, enabling safe opening and closing of circuits with high power demands.

Features and Types:

- AC or DC Coil Contactors: Chosen based on the circuit type. AC coil contactors are generally quieter.

- Main Contacts: Typically three in three-phase contactors, made of copper or silver-coated materials for conductivity and durability.

- Auxiliary Contacts: Provide additional signals for control circuits based on the main circuit's status.

Applications:

- Motor Control: For industrial motors' start/stop operations.

- Lighting Systems: Managing high-power lighting in large facilities like factories or hospitals.

- Heaters and Power Sources: Safe operation of high-power heating equipment.

2. What is a Protection Relay?

Protection relays detect conditions like overcurrent, short circuits, or ground faults and isolate the circuit to prevent damage. They work in conjunction with contactors or circuit breakers.

Features and Types:

- Thermal Relays: Protect motors from overloading using bimetal strips that deform under excess current.

- Magnetic Relays: Operate during short-term high currents, such as inrush currents.

- Earth Leakage Relays: Detect ground faults, preventing shocks and fire risks.

Applications:

- Electric Motors: Safeguarding against overloads and faults.

- Generators and Transformers: Protecting expensive and critical power equipment.

- Industrial Facilities: Securing power distribution systems.

3. What is a Fuse?

A fuse is a sacrificial device that protects a circuit by melting its conductive element during overcurrent situations, thus interrupting the flow.

Features and Types:

- Ampere Ratings: Selected based on the circuit’s maximum current requirements.

- Fast-Acting and Slow-Blow Fuses: Quick response for short circuits versus tolerance for transient surges.

- Types: Glass tube, blade-type, and automotive fuses vary in design and application.

Applications:

- Residential Wiring: Preventing appliance damage.

- Automotive Sector: Low-voltage circuit protection in vehicles.

- Industrial Panels: Protecting sensitive components.

Comparison: Contactor, Protection Relay, and Fuse

| Feature | Contactor | Protection Relay | Fuse |

|---|---|---|---|

| Function | Controls circuit on/off | Protects against faults | Cuts circuit in overcurrent |

| Reusability | Yes | Yes | No, single-use |

| Operating Mechanism | Electromagnetic switching | Fault detection and isolation | Melting conductor |

| Usage | Motors, lighting, heating | Industrial safety | Residential, industrial panels |

4. What is a Switch?

Switches are mechanical or electronic devices that open or close electrical circuits. Key safety applications include emergency stop switches and safety gate switches.

Types and Features:

- Emergency Stop (E-Stop) Switches: Instantly cuts power during emergencies. Typically red and easy to access.

- Safety Gate Switches: Halts machine operation when safety gates are opened.

- Position Switches: Detects the position of machine parts and interrupts operation at specific positions.

Applications:

- Industrial Machines: Emergency shutdown.

- Safety Systems: Preventing unauthorized access.

- Factories: Position and operational control.

5. Sensors and Their Functions

Sensors detect specific parameters and send signals to control devices. They play a vital role in enhancing safety by preventing accidents.

Types and Features:

- Photoelectric Sensors: Detect light for operational triggers.

- Proximity Sensors: Identify nearby objects, preventing accidents.

- Current Detection Sensors: Monitor current flow and halt operation during irregularities.

Applications:

- Industrial Automation: Ensuring safe machine operation.

- Safety Systems: Detecting hazardous conditions.

- Workplace Safety: Monitoring high-risk zones.

Importance for Occupational Safety and Health

1. Preventing Electrical Hazards

- Protection Relays: Detect earth leakages and prevent electrical shocks.

- Fuses: Eliminate fire risks by mitigating overcurrent conditions.

- Contactors: Ensure controlled operation of high-power devices.

2. Safe Maintenance

- Components allow easy circuit isolation for safe maintenance.

- Proper selection extends equipment life and enhances worker safety.

3. Compliance with Standards

- Adhering to regulations like EN ISO 13850 ensures legal compliance and safeguards workplace safety.

By effectively utilizing these components, risks such as electrical shocks, fires, and operational failures can be minimized, ensuring a safe working environment across industries.

Comments