Ball Screw and Trapezoidal Screw: Differences, Types, and Applications

Ball screws and trapezoidal screws are mechanical components frequently used in systems requiring precise motion transmission and positioning. Each component has its unique design, advantages, and application areas. This article provides a detailed analysis of ball screws and trapezoidal screws, focusing on their differences and when they should be preferred. Furthermore, the technical specifications and production methods of both systems are explored in more detail.

What is a Ball Screw?

A ball screw is a mechanical component designed to convert rotary motion into linear motion. It is typically used with ball nuts to provide precise and efficient motion transmission. Ball screws are commonly found in CNC machines, industrial robots, medical devices, and automation systems. These features make them indispensable in modern industrial systems requiring high precision and efficiency.

Ball Screws by Lead

-

Short-Lead Ball Screws:

- Designed for smoother and more precise motion.

- Used in applications requiring accurate positioning.

- Example applications: CNC machine tool units, optical systems, medical devices.

-

Long-Lead Ball Screws:

- Manufactured for faster motion.

- Used in applications prioritizing speed but generally offering lower precision.

- Example applications: high-speed transport systems, loading robots.

| Diameter (mm) | Lead (mm) |

|---|---|

| 16 | 05, 10, 16* |

| 20 | 05, 10, 20* |

| 25 | 05, 10, 25* |

| 32 | 05, 10, 32* |

| 40 | 10, 40* |

*Long-lead ball screws.

Ball Screws by Production Method

Ball screws provide different levels of precision, durability, and cost depending on their production method. These characteristics allow for selection based on application requirements.

-

Rolled Ball Screws:

- Manufactured using a more economical process.

- Offer lower precision compared to ground ball screws.

- Used in systems requiring light loads and lower precision.

-

Ground Ball Screws:

- Preferred for applications requiring high precision and durability.

- Provide minimal backlash and wear.

- Suitable for high loads, often used in CNC machines and precision robotic systems.

| Production Method | Load Capacity | Precision | Application Area |

|---|---|---|---|

| Rolled | Medium | Medium | General mechanical applications |

| Ground | High | High | Precision industrial systems |

What is a Trapezoidal Screw?

A trapezoidal screw is a component with trapezoid-shaped threads, typically used in applications requiring low-speed motion conversion. Trapezoidal screws have a simpler design and are more cost-effective compared to ball screws. Thanks to their thread design, they have a high load-carrying capacity and are commonly used in heavy industrial applications.

- General Characteristics:

- High load-carrying capacity.

- Self-locking capability prevents backlash.

- Cost-effective and simple design.

- Example applications: press machines, heavy load lifting systems, marine equipment for corrosion-resistant applications.

| Diameter (mm) | Lead (mm) |

|---|---|

| 16 | 04 |

| 20 | 04 |

| 25 | 05 |

| 30 | 06 |

| 40 | 06 |

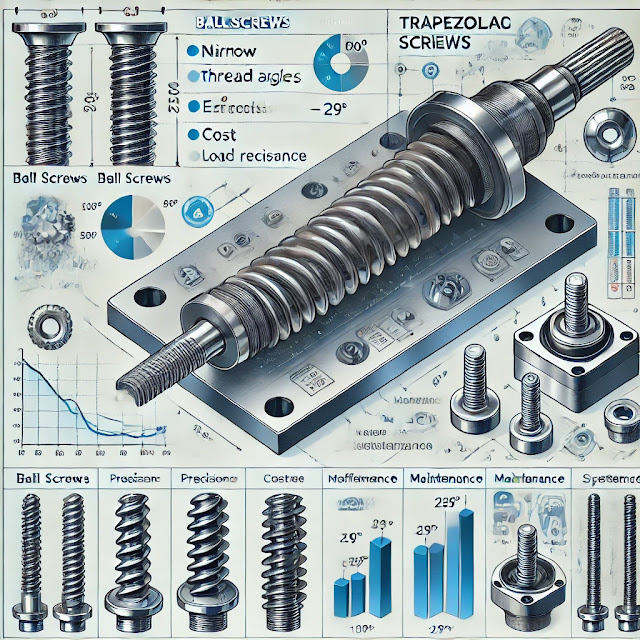

Differences Between Ball Screws and Trapezoidal Screws

The fundamental difference between ball screws and trapezoidal screws lies in the design and angle of their threads. Ball screws typically have a narrower thread angle, enabling precise motion. Trapezoidal screws, on the other hand, feature a wider thread angle, offering a simpler and more robust structure. While ball screws are preferred for high-precision and fast applications, trapezoidal screws provide more durable and cost-effective solutions.

| Feature | Ball Screw | Trapezoidal Screw |

|---|---|---|

| Thread Angle | Narrow (<10°) | Wide (~29°) |

| Precision | High | Medium |

| Efficiency | High | Medium |

| Cost | Higher | Lower |

| Maintenance | More Frequent | Less Frequent |

| Backlash | Minimal | Prevented by self-locking |

| Load Resistance | Medium | High |

Conclusion

Ball screws and trapezoidal screws are components designed for different applications. Ball screws provide precision, low friction, and high speed, while trapezoidal screws offer durability and economic solutions. Selecting the right component based on application requirements directly impacts system performance and durability. For example, ball screws are ideal for high-precision CNC machines, while trapezoidal screws are advantageous for heavy load-bearing applications. Considering the unique features of both types, choosing the appropriate one ensures cost-effectiveness and functionality.

Comments